Validation and Testing

CUSTOM TESTING

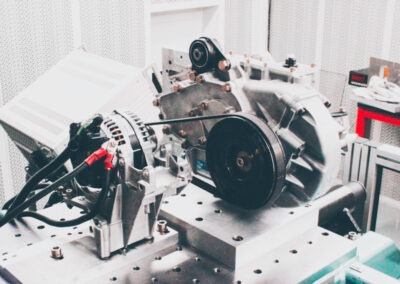

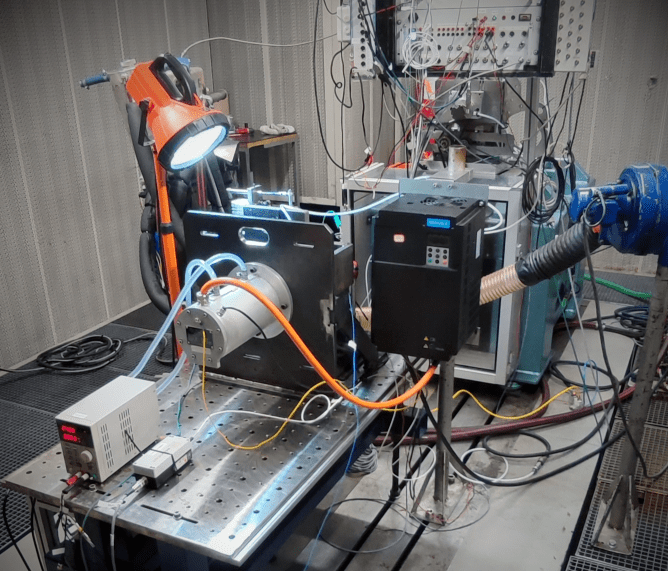

With over 30 years of experience, the company has the means and skills to assemble the most complex prototypes and perform all validation tests on adapted test benches.

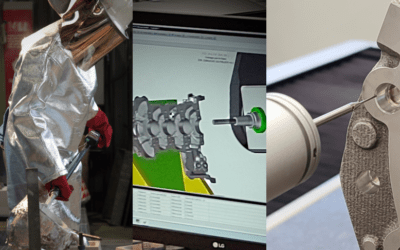

Our associated services of design office, foundry, machining and boilermaking facilitate the adaptation of test equipment according to your request.

skills for

the assembly of demonstrators

DANIELSON Engineering has confidential assembly boxes. Specific tools are studied and produced in-house.

-

assembly plan

-

shooting

-

static measurements

-

adjustment

-

debugging

skills for

the measure

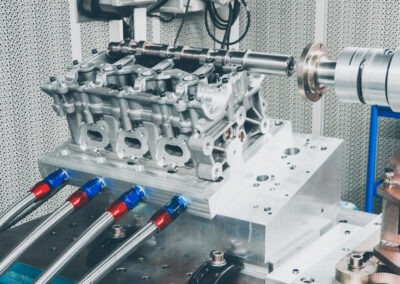

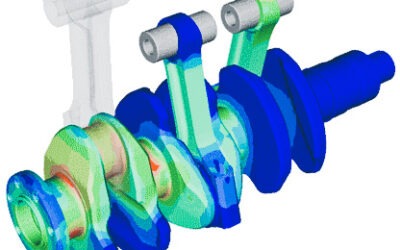

This department carries out the instrumentation adapted to the experience plan established for the characterization or validation of the prototype

- torque measurement

- pressure measurement (fast or slow)

- vibration measurement

- temperature measurement

- analysis and presentation of results

We perform pressure, speed, vibration and temperature measurements, simulating the most severe conditions of use. All results are recorded for subsequent analyses.

DANIELSON ENGINEERING has air heater cells to perform tests up to 55°C of ambient temperature to validate cooling systems.

We perform dynamic tests on vehicles to obtain measurements on board. Test runs of 40 km covering a representative diversity of driving conditions are set up.

They allow failure analysis and thus make the systems more reliable.