machining

CUSTOMIZED MANUFACTURING

The mechanical manufacturing department of danielson engineering is equipped with modern means for producing parts and complex assemblies in small series for the of defense and aeronautics sectors, as well as prototypes for the automobile and the competition sector.

In conjunction with the foundry department, we offer to control of the entire value chain until the delivery of complete sets.

skills for

the machining of complex parts

DANIELSON Engineering is equipped with:

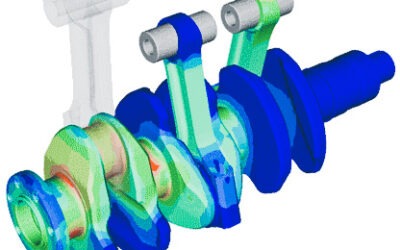

- an integrated methods office equipped with TOSOLID

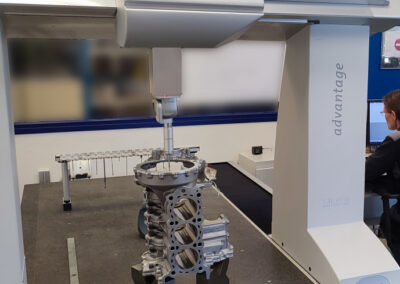

- an air-conditioned metrology room with maturation chamber

- MMT with remote programming

- a tool station with ZOLLER bench

- of centers 5 axes webbed

- a turning/milling machine

- with a two-pin digital lathe

- a camshaft grinding machine

- a cylindrical grinding machine inter/exter CN

- a flat grinding machine

- a finishing station

- an engraving station

- equipment stations with oven and hydraulic press

- a leak control station

An internal DTP software allows us to track and maintain the traceability of the parts we manufacture.

Our teams are trained to the aeronautical requirements standard.